Enhance the effective utilization of resources and expand Chinese tantalum and niobium ore output

----Interview with Mao Meixin

Director

Jiangxi Jiangte mining development Co. LT

- Jiangxi Jiangte mining development Co. LTD was set up in 2011 and located in Yichun, Jiangxi. It is established by Special Electric Motor Co.,Ltd with a registered capital of 50 million yuan. There are 5 son companies. The main products are Lepidolite concentrate, tantalum and niobium concentrate and Lithium feldspar powder and kaolin.

- Asian Metal: Hi Mr. Mao, Thank you for taking part in this interview. Could you please give us a background on your company and its current state of production?

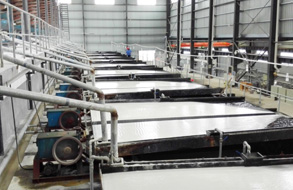

- Mao: Our company was set up in 2011 and located in Yichun, Jiangxi Province and owned by Special Electric Motor Co., Ltd. The plant has an annual production capacity of 60t and now is building a dressing plant with a processing capacity of 1200000tpy. The project will be finished in April, 2018 and the output may reach 120tpy of tantalum ore at that time.

- Asian Metal: What about the production areas and consumption situation in both domestic and overseas market?

- Mao: Brazil has rich niobium ore resources with high quality which covers 90% of the global niobium resources. The other niobium is usually along with the tantalum materials. Most of niobium is used on ferroniobium and small quantity is used at electronic and aerospace area. In China, the niobium and tantalum is associated.

- Main production areas for tantalite are Australia, Congo, Nigeria, Canada and so on. The output from Congo is big. The main provinces in China are Jiangxi, Xinjiang, Guangxi, Fujian, Guangdong and Hunan. Tantalum is mainly used in electronic industry and small quantity is used in metallurgy and aerospace.

- Asian Metal: Compared with overseas tantalite producers, what are the advantages and disadvantages of domestic tantalite producers?

- Mao: Chinese domestic tantalum and niobium resources are mainly in Jiangxi, Xinjiang, Hunan and Fujian provinces. Especially Yichun, as it is opencast working with good operation conditions and high comprehensive utilization of resources, it can produce not only tantalite but also lepidolite and feldspar. The quality of tantalite is good in Yichun area. The disadvantage for domestic tantalite producers is that some area has low grade with high difficulty of dressing. Compared with the overseas producers, the output in domestic market is limited which cannot satisfy the require from Chinese smelters.

- Asian Metal: What is the advantage and disadvantage of your company in tantalum industry?

- Mao: As our company is a listed company with strong financing capacity and many professors. We invest a lot of money on the development of research and innovation to ensure the high usage of resources. As a by-product of Li, our tantalite output will increase along with more output of our Li products. At the same time, we are also active in finding new ores and investment project on related materials. The disadvantage is that our current output is at a low level with a bad quality of resources. We will try to invest more on the recycling and usage of resources and improve the comprehensive utilization of resources.

- Asian Metal: What is the future plan or main product of your company?

- Mao: Li ore is our main product. As the demand for Li grows these years, in order to satisfy more orders from downstream clients, we begin to build new plants. As a by-product of Li, the production capacity of tantalite will also increase accordingly.

- Asian Metal: What are downstream industries for tantalum and niobium? Which area is the main focus on development?

- Mao: Electronic and metallurgical industries are the downstream industries. I think that the electronic industry will be more important and promising.

- Asian Metal: The supply from African and South American market remains tight with increasing prices this year. Do you think it will influence the Chinese market prices?

- Mao: Chinese domestic market supply is still limited and the mainstream price depends on the African materials. The Chinese tantalite capacity is far from the average production capacity of the international market. The total output of the tantalite in Chinese market is around 400t per year, which can only satisfy 10-15% of the domestic need. China acts as the biggest consumption country for tantalite, which consumes more than 90% of the tantalite in the world. The developing room is huge in the future while the Chinese tantalite price cannot influence the global market price in the near term.

- Asian Metal: Thanks again for taking our interview, and wish a more prosperous future for your company.